Russia’s advantage in laying and defending mine fields was one of the prime reasons the Ukrainian counteroffensive failed in 2023 and it is one of the main reasons Ukraine is not able to break through mine fields unless it has the element of surprise.

The Russians are heavily reliant on their mine fields to maintain the front, especially as they thin out the reserves in the rear to divert manpower to Kursk.

In this post, I will set out a system that can turn the tables and eliminate the enemy’s advantage in defense. The key is a cheap survivable system that can quickly demine large areas.

The advanced version starts at 128k for a 1.5m path clearance and the simple expendable version starts at 20k for a 1m path clearance.

Note that it is potentially inferior to the new Thermite drone the Ukrainians just developed in terms of speed, cost and survivability.

Mines should degrade around 400 degrees and thermite is 1500 degrees so it could cook off mines buried up to 50 cm below the surface.

In any case, you will want to pass a mine roller like the Dafuq before you send in actual vehicles.

What are the demining challenges?

Mine fields are a challenge in any war but Russian mine fields are one of the hardest to crack.

Anti-tank mines need a lot of pressure to activate

To clear a mine field you need to apply 6k kPA on almost every area of the battlefield.

That’s a very hard requirement.

Anti-personnel mines detonate at much lower pressure so if you can clear for anti-tank mines then it’s also clear for personnel.

Russia can aerially deploy minefields

The Zemledeliye is a formidable system and can lay 12000 mines in a single volley.

Any cleared mine field can be remined in 10 minutes.

Russia constantly monitors their mine fields

Any mine-clearing vehicle or infantry will be immediately targeted and their work will be undone by redeployment of mines.

During the counteroffensive, mine vehicles were destroyed and the tanks coming up behind them got stuck in the middle of a minefield and had to drive backwards.

Survivability of the deminer is critical as it will be targeted by drones, artillery, missiles and everything that even remotely flies.

Russia has a wide variety of mines

Diversity of mines is a strength as no single mine-clearing method is likely to work.

Russia mixes up anti-tank mines and anti-personnel mines of both magnetic and non-magnetic sort.

Russia has a lot of mines

At the start of the war they had 14 million mines.

It’s unlikely they will ever run out of mines.

They have a limited amount of Zemledeliye’s though, those could potentially be exhausted but Russia also has artillery-based and other forms of aerial deployment.

Terrain varies a lot

You need a vehicle capable of moving over uneven terrain and apply pressure in craters.

Russian mines are blast-resistant

Just dropping a thermobaric bomb that generates enough overpressure is not sufficient to trigger the mechanism of mines.

Russian mines are heat-resistant

Although it should be possible to use your new termite drone to torch a path through a mine field, Almost any mine degrades at 400 degrees.

The deminer gets blown up a lot

Needless to say, it sets off mines so it is on the receiving end of quite a few explosions but also it gets targeted by artillery, missiles, glide bombs, kamikaze drones and whatever the Russians can get on-target.

Problems with current deminers.

They are pushed by vehicles

Vehicles are easy to take out and hard to hide.

The main reason there is a vehicle though is propulsion of the roller.

The vehicles have real people inside

Drone deminers exist (e.g. DOK-ING mv-4) but most are driven by people.

They’re like enterprise software products

They do too much.

The DOK-ING mv-4 can explore “situations” with a robotic arm, why?

You need it to create a safe path for tanks and IFV vehicles.

At most you want to highlight specific areas as to be avoided.

They’re way too expensive

So many features but they are easy to blow up.

Demining equipment should be cheap because you’ll need a lot of them.

Ideally, you would be able to repair the deminer under fire or make it so cheap you don’t care about losing them.

They’re not fast enough

They go 5-10km/hr which is a problem when you are under fire but it leads to the next problem:

They create predictable paths

The Miclic for example, only creates a linear path.

Other deminers create just one path because they are really slow.

If a vehicle breaks down in that path it’s effectively trapping tanks behind it.

What you really want is a system that can create many unpredictable paths and the ability to create new paths quickly.

Double-fuse and delayed-fuse mines

First one rolling over arms the mine, the second one detonates the mine.

Or just the first one starts a timer.

Alternatively, put a metal plate that spreads the weight of the roller over a wider area but still detects the Tank.

In any case, one can invent mechanisms to make the vehicle vulnerable behind it.

PTKM-1R

Recently developed mines that detect the sound and vibrations of a vehicle in the area and attacks it with a small missile.

This one is not aerial deployed and is very recent.

It’s unlikely they have this mine in large numbers.

TM-83

Armoured projectiles hitting from the side and is activated with infrared or acoustic sensors.

Some constraints for the solution

1. You can’t hide a mine clearing vehicle.

It’s going to blow up mines.

Which means you have to assume it will be detected and attacked.

2. It can’t defeat all mines

There are too many different types.

You could deploy different deminers in rapid succession or you could mark ‘suspicious ground’ that should be avoided.

But the most common ones (magnetic, pressure-activated, rod-activated, delayed fuse, trip wire) should be taken out reliably.

3. There shouldn’t be an obvious way to stop it

Digging a trench, setting some dragon teeth, …

Whatever it is, the vehicle should be able to pass over it or a drone or airstrike should be able to unblock the vehicle.

4. It should be able to demine the same area quickly and repeatably.

Aerial deployment of mines means that mine fields will be redeployed quickly so you need to be able to clear quickly also.

5. The area should be surveilled first with drones

Drones exist that can map the top surface and the surface below.

- Lidar

- Magnetometer (Magdrone)

- Ground penetrating radar

It can be used to pre-plan paths through the mine field that seem unlikely to hit mines and plan a path through terrain the Dafuq mine roller is actually able to navigate.

Steel segmented rollers are superior

They can apply the necessary pressure everywhere (6kPA) while rolling over terrain and if a roller passes then all types of mines are triggered.

The steel segment will trigger magnetic mines and the heavy weight will trigger any pressure mechanism, in addition it will look and sound like an armored vehicle.

Rollers tend to be cheap and easy to replace which is not true of the harness and the vehicle that pushes them forward.

The segments of the roller allow the deminer to follow the terrain and the shape enables traction in muddy soil and also concentrates the weight on a narrower area.

Propulsion should be embedded in the roller

Killing the propulsion is the easiest way to take out the deminer.

But that would be super hard if it’s embedded inside a blast-proof roller already designed to survive explosive blasts.

Embedding electrical propulsion inside the roller is the main innovation in this post.

It enables the roller to move forward and backwards at will but also it allows precise control over the torque applied to either the wheel or the connecting shaft.

Propulsion should be embedded in the roller

Energy supply and control

Energy can be delivered by wire directly to it and also control of the vehicle can be done through a wire. The reason is that this system requires a lot of power and mine fields are usually the first line of defense encountered so a wire can be run to the demining team.

It’s important that wires can be (re-)attached by drones

Some magnetic method similar to a magsafe adaptor would be best.

It’s important because the wires are a vulnerability and you want to make sure you can repair the wire connection in the field.

Given that kamikaze drones are likely to attack this connection, it’s important that there is a lot of redundancy in connection points and the connector on the vehicle is likely to survive a direct attack.

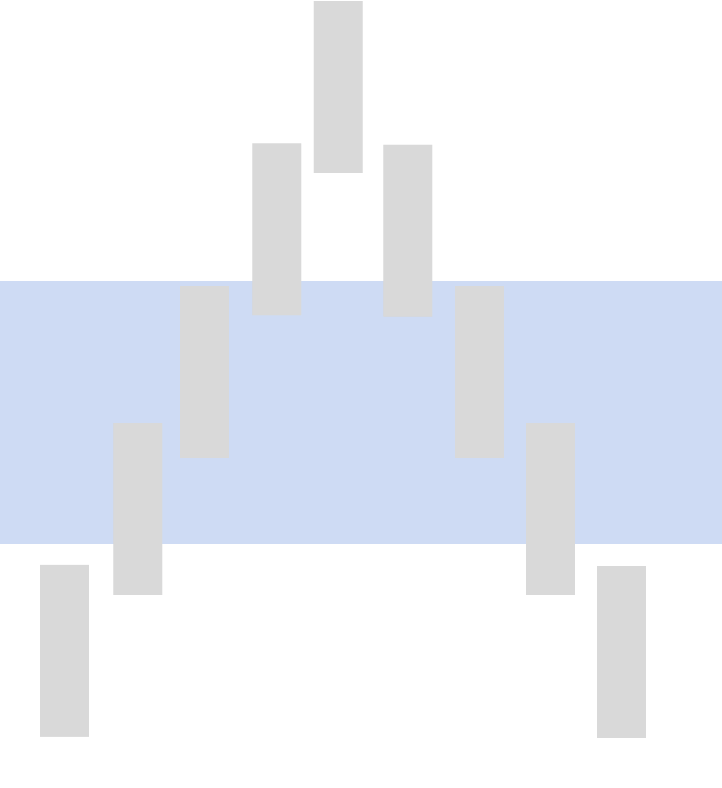

Cross-country ability

Deminers should be able to cross any terrain and the deminer has to be able to apply the 6kPA pressure over uneven terrain.

However, the vehicle needs to maintain its stability while also being easy to repair when damaged.

The proposed design is like a crankshaft.

This gives it inherent stability but also wheels can drop down into craters or go up.

Since each wheel has its own torque, the concrete wheel can lift itself and “flip”.

This is useful to arrange itself in V formation to cross trenches or to move the front wheels forward onto higher elevations.

Potentially this means it could climb over dragon’s teeth obstacles but you should check my next post on how to defeat static fortifications.

The V-shape can also be used to provide infantry with shelter against artillery or hostile fire when assaulting the enemy’s fortification.

Although if infantry protection is needed you should probably design it to turn like this toy as you can create arbitrarily weird fortification structures.

In any case, putting the propulsion inside the wheels creates a lot of opportunities.

Steering

If you can turn each wheel in any direction then you can easily turn.

This allows you to navigate around objects, create unpredictable paths and follow roads like a normal vehicle.

Repairability

Due to the weight of the wheels, the vehicle has to return to base to be repaired but since it is highly composable of segments, it’s easy to replace a segment similar to how it’s easy to replace a chain link of a bicycle chain.

As stated, the electrical connection should be “repairable” by drone, this can be done by a magnetic adaptor (cfr. magsafe adaptors).

You could design the vehicle to “split” (e.g. both sides detach from an intermediate chain) and reconnect later. This would enable you to abandon a broken segment in the field or to drive back just the broken segment back to base.

That would be future work though.

Marking safe passage

It’s better drones do this then the mine roller, it’s a point of vulnerability and adds unnecessary complexity.

How fast does it go

It has an acceleration of about 5 meters/second (18km/hr) and could go very fast.

It depends on the terrain conditions how fast but it should match tank speeds of 60km/hr.

Which means it takes 10 minutes to cross a 10km mine field.

In practice you will need to vary the speed to make sure you apply pressure everywhere a tank would apply pressure but this can be pre-planned before the operation.

It can easily turn and come back.

Wheel design

To have the wheel flip, it should be as light as possible but in order to detonate the mine you need 6kPA applied to every surface area.

The Prokhod has an interesting groove design that enables that, maximizing pressure on a smaller surface area so that it reaches the desired pressure with less volume.

It looks like they managed to get it to 70cm diameter based on the size of the T-90 wheels.

That wheel weighs about 200kg which would trigger a mine but they make sure to only apply it one side of the wheel which means the weight on the surface line is around 400kg which would setoff any mine.

The wheel is also metalic, which will set off any metal-detecting mines.

There are two wheels after each other to trigger dual-fuse mines.

Choice of electric motor matters a lot

There is definitely a weight-torque tradeoff in the Electro motor choice.

The wheel needs two electric motors (one for each attachment point) for maximum flexibility and to be able to overcome obstacles (more details below).

That means the thickness of each electric motor matters because you will have to put two of them next to each other.

The motor can be swapped out by other types but I will pick the Yasa 750 R motor as it is electric, thin, light and can deliver a lot of torque.

The Yasa 750 weighs 37kg and can generate 700 nm torque and costs around $15k.

It is also only 10cm deep so you can have two of them in 20cm and still leave room for armored plating to protect the motor.

The engines need armored plating and shock-dampers to be able to survive mine blasts and drone attacks.

An armored plate of 40cm diameter and 2 cm thickness should do.

That would add an estimated 20kg to the vehicle (e.g. Mil-a-46100e grade steel)

That brings the additional weight to be added to a roller to:

2 x Yasa750 + 2x armored plate = 2x 37 + 2x 20 = 114 kg.

There would also be some power electronics and a computer so let’s round it up to 120kg.

Existing rollers could be adapted

There seem to be rollers that have a relatively large area where the engines could be incorporated.

Let’s assume we have wheels of 400kg

It’s enough to trigger the mines and leaves enough space for the actual roller weight.

The Pearson engineering rollers are battle-tested and seem like they can be adapted.

They also seem relatively lightweight which is good (lighter is better).

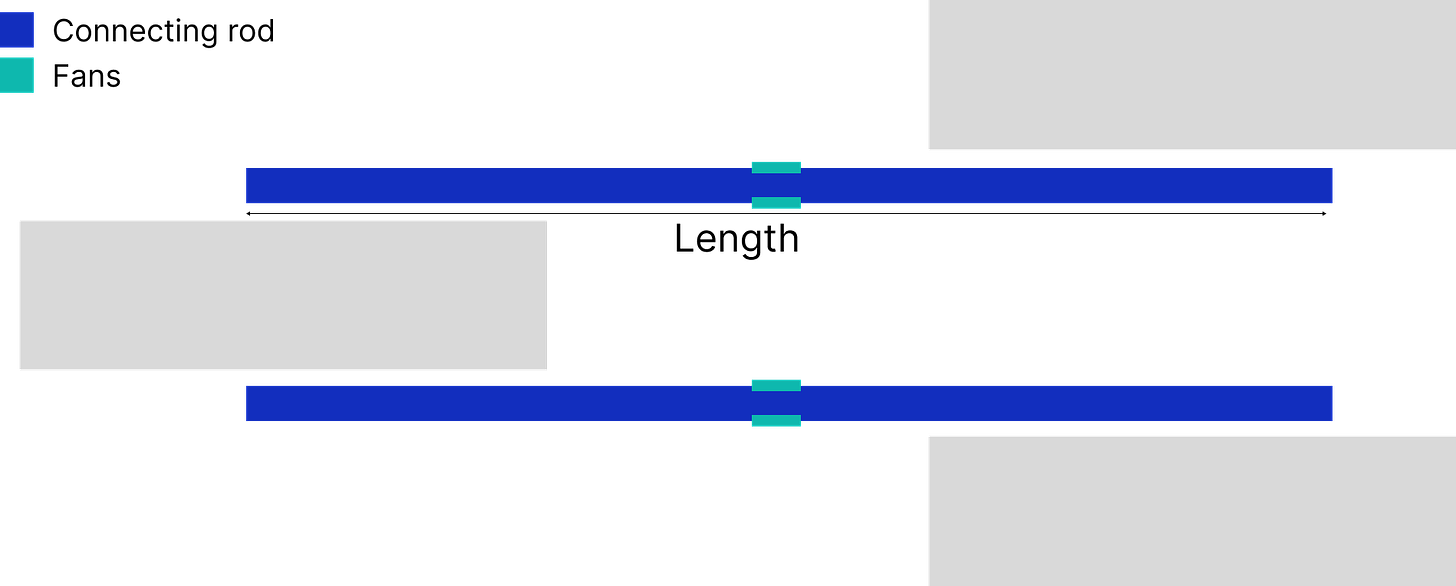

Connecting rod design

The rod has to be made from blast-resistant material but it has to be hollow inside as both air, electricity and control is going to pass through it connecting all the wheels into a centrally powered and controlled vehicle.

Cooling is going to be needed.

I am not sure how much cooling those electric motors will need but there should be fans blowing wind through the system, those can be mounted in the middle of the connecting rod.

Other connections could be mounted there too like the electrical connection but that’s probably better near the axis as that connection is unlikely to survive a blast anyway.

Longer rods are better for mobility but worse for controlled flipping

It’s a matter of physics unfortunately.

Lifting the weights at a longer distance is pretty difficult thanks to the lever-effect.

The rod should be hydraulically extendable

This would allow us to shorten the rod before flipping, drastically reducing the engine requirement for doing so.

It’s important that the hydraulic arm remains encased in armored steel, if it would become exposed it would be a prime target for drones.

The wheel will flip when it detonates

First off, when a wheel blows up the explosive force will likely flip the wheel.

The electric motor will become a generator for a very short time, so any power electronics will have to be aware of that.

Flipping the wheel

The simple solution is to detract the rod to its minimal length (e.g. 0.5 meters) and then use the existing torque of the 4 engines to flip.

The metal rod also has a weight, let’s assume 50kg.

450kg at 0.5m with a 9.81 m/s^2 gravity acceleration generates about x torque

F=450kg×9.81m/s2=4415N

τ=0.5m×4415N=2207.5Nm

Each wheel has 2 axial motor engines and they can work together to combine their torque. Similarly, the engines on both wheels can work together as torque generated is transferred through the metal rod to the ground point.

That gives us 4 engines with 700nm torque, which is 2800 of torque.

The bar could be a bit longer (0.6m) and it would still work.

But there’s a much cooler solution to this.

Kinetic batteries

Flipping the wheel is one thing but we could use flywheels to build up a kinetic energy battery that when brutally stopped would transfer all this kinetic energy into torque.

The design of the vehicle allows for multiple kinetic battery options.

1. Air battery

The hydraulic arm could be used to compress air when retracting. This same air could be released on a fluid rapidly expanding the hydraulic arm.

2. Armored plating inside the wheel

Every wheel has 2 armored plates but you could design them that they can be rotated by the axial flux motor. If you connect it without any gear box then the plate could be spinning at 3250 rpm (max rpm of the Yasa 750).

Unmodified, a flat armored plate will generate about 19k Joule.

If we manage to abruptly stop the plate from spinning (by for example rapidly releasing hydraulic pins) so that it applies all this energy to the arm.

Let’s assume we can stop it in 200ms.

That would generate another 570 nm in torque and we have 4 of these disks.

So in total we could generate 4x 570nm = 2280 nm in additional torque.

The kinetic storage of this plating could be enhanced by making it heavier at the edges.

3. We could spin the entire wheel

This would have to be done at 0.5m bar length but we could lift it and then start spinning the entire 400kg wheel.

We could again use hydraulic-powered pins to abruptly stop the wheel from spinning in 200ms.

This would generate 41k nm of torque.

3. We could swing an entire wheel along its arms.

Imagine a roller with 5 wheels.

We could use the previous mechanisms to lift 2 wheels in the air and then shorten the arms hydraulically to lift the wheel between them from the ground.

Then we start swinging the wheel back and forth adding momentum.

Unlike the kid, you can let the wheel gain momentum until it starts to come back full circle.

Let’s assume we build this up until the wheel is doing 1000 rpms and then we extend the hydraulic arm again to increase the lever effect to 1 meter long.

It’s unlikely we can stop this behemoth in 200ms but if we would, it would generate 209k nm of torque.

Does it jump?

Let’s see.

A vehicle with 5 rollers (minimum configuration) would weigh 2.5kg (400 for the wheel and 100kg extra for the bar).

The resting force is 9.81*2500 = 24525 ≈ 25kN

The momentum we can bring to bear is 209kNM at 1 meter distance ≈ 209kN

It scales horizontally, so a Dafuq with 20 rollers would be able to jump too.

It absolutely jumps.

It would jump about 8 meters high if the this force would be directed vertically…. at least theoretically.

It could jump over obstacles like dragon’s teeth and anti-tank ditches (and maybe trees).

However, I’ve got something more efficient for that.

How much does it cost?

Off the shelve, the Yasa 750 costs $15k but you can get a volume discount probably that brings it down to $10k.

The reinforced steel is about $7usd/kg and you need 60kg per wheel and maybe another 10kg for the mechanics and connecting rod which sums up to about 500 usd per wheel.

The only other big cost is the wheel, which I suggest also to get a volume discount on.

It should weigh around 300kg so at $7usd/kg that’s 2100 usd.

Add 1k in labour costs and 2k cost of electronics.

2x10,000+500 + 2100 + 1000 + 2000 = 25600

Because the system is very fast and there is no vehicle behind it, it doesn’t have to be 4m wide.

If the wheel base is 30cm then a 5-roller would clear a 1.5 meter wide strip.

The Dafuq could clear a 6m passage by passing over 4 times.

The minimum cost is $128k for a 1.5m clearing and the costs scale linearly with width.

A 6m wide system would cost around 512k

There is a budget option.

Now, the cost of the motor is the most important but you could in fact make the wheels much cheaper by putting cheap and heavy motors instead.

If you drop the flipping requirement and you make the wheels expendable (no survivability) then you could use heavy industrial electro motors in a simple concrete wheel.

You will have to drag back the deminer and replace the wheel every time though so you need to build many.

Simple electric motors cost about 500 eur and a hard-concrete casing costs about the same.

It would mean the same system costs

2x500+ 500 + 2100 + 1000 + 2000 = 6600

If flipping is not needed then three-wheeled rollers are better.

This means one system costs ±20k and can clear a 90cm path.

120k can clear a 5.4m path

Why is it called Dafuq?

Cause it is a jumping mining vehicle.

It’s also the sound Russians would make when they see this in action.

Aaand, it’s a pop culture reference for to dafuqboom, a Gen X internet legend for the creation of Skibidi toilets and the Male_07 universe.

Note that watching all his videos is likely going to erode your faith in the future generation ;)

Gen X soldiers will love it.

Check out this gem for the reference:

That’s how we roll.